Submit feedback

Nonwoven Cleaning Cloth Manufacturers

Non-Woven Cleaning Cloth

Non-woven cleaning cloth is a versatile and eco-friendly cleaning tool, manufactured from staple fibers or continuous filaments, which are bound together mechanically, thermally, or chemically. Unlike traditional woven fabrics, these cloths are not made by knitting or weaving, which gives them a unique texture that is soft yet robust enough for multiple cleaning tasks.

Non-woven cleaning cloths offer high levels of absorbency due to their porous nature, making them ideal for wiping up spills and cleaning surfaces without leaving streaks. They are typically lightweight and have a non-abrasive surface which ensures they are gentle on a variety of surfaces, from glass and stainless steel to wood and composite materials. The open spaces in the fibers allow dirt and liquid to be trapped easily, which enhances their cleaning efficiency.

Non-woven cleaning cloths are designed for convenience and are often disposable, creating a hygienic solution that reduces the risk of cross-contamination between cleaning areas. Reusable varieties can also be found, which can be washed and reused multiple times, extending their life and serving as an economical and environmentally friendly option.

Moreover, they come in a range of colors, which supports color-coded cleaning systems that help prevent the spread of bacteria from one area to another. They are widely used in households, as well as in industrial, healthcare, and hospitality settings, attesting to their adaptability and effectiveness in various cleaning roles.

JIAXING HONGJIE COMMODITY CO., LTD

JIAXING HONGJIE COMMODITY CO., LTD is famous China Nonwoven Cleaning Cloth Manufacturers and Nonwoven Cleaning Cloth factory, an enterprise combining industry and trade. The factory is located in Jiaxing City, Zhejiang Province, adjacent to Shanghai and Hangzhou. The company is committed to producing various non-woven products, including non-woven cleaning rags, non-woven wet wipes, non-woven mops, disposable dusters, and other related non-woven products.

The company has more than 10 rag production lines, 2 fully automatic wet wipes production lines, duster production lines, and several other product production lines. They are mainly exported to dozens of countries such as the United States, Europe, Japan, South Korea, Australia, and Southeast Asia. Among the cooperative customers, there are many well-known supermarkets and purchasing customers at home and abroad. A complete set of production processes and management theories allows us to have stable quality and supply capabilities, winning unanimous praise from customers. At the same time, we also welcome new customers to inquire and visit our factory and look forward to establishing long-term cooperation with you.

AUTHENTIC RELIABLE QUALITY NATURALLY STANDS OUT AND FEARS NO COMPARISON.

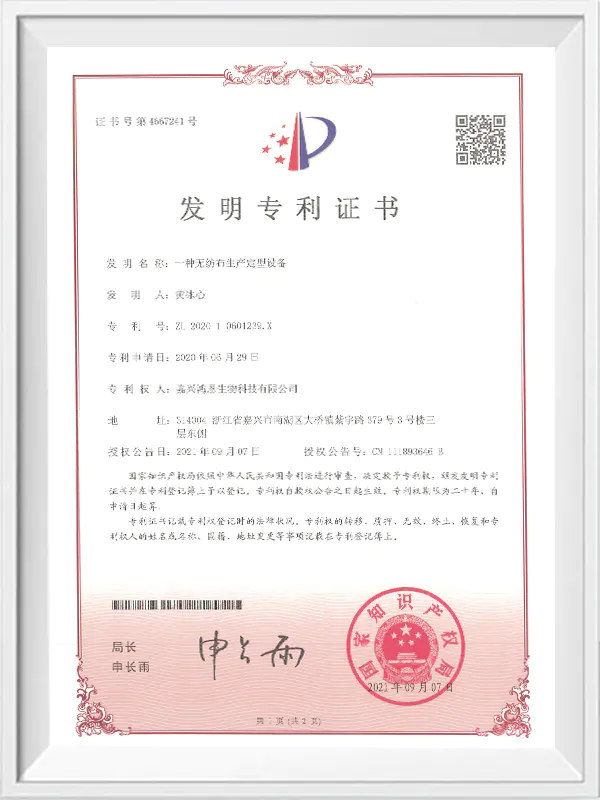

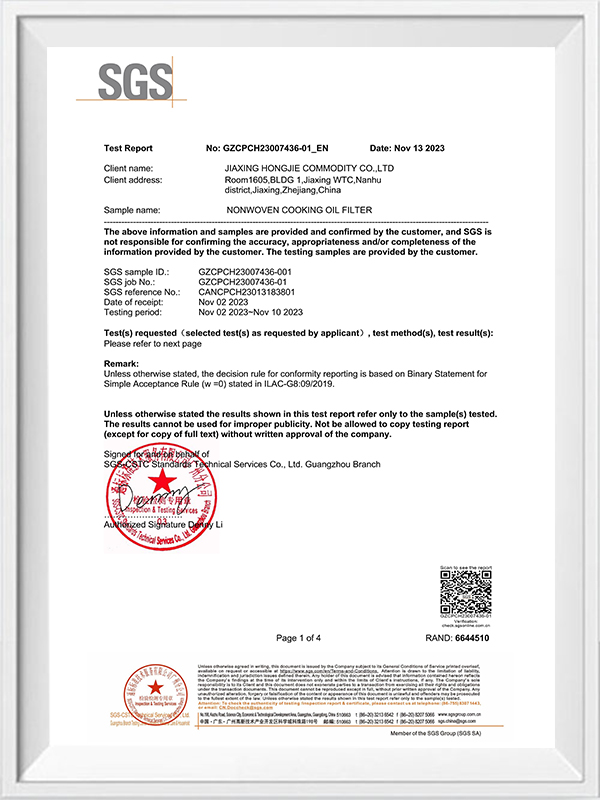

We focus on high-quality cleaning nonwovens and attach great importance to product quality certification. In order to let customers choose our products with confidence, we will continue to work hard to improve product quality, provide customers with better products and services, and actively support the development of the quality management system.

-

2026-01-23

How Do Pet Cleaning Wipes Improve Convenience Without Compromising Safety?

The Rising Demand for Pet Cleaning Wipes in Daily Pet Care Pet cleaning wipes have become a staple in modern pet care routines as owners look for fast...

-

2026-01-16

How Are Household Cleaning Cloths Adapting to Smart Home Cleaning Tools?

Introduction to Household Cleaning Cloths Household cleaning cloths are essential tools for maintaining hygiene and cleanliness in modern homes. Tradi...

-

2026-01-06

How to choose secure personal wipes?

Introduction to Personal Wipes Personal wipes are an essential hygiene product used in homes, workplaces, travel, and healthcare settings. They provid...

-

2026-01-04

What Innovations Are Emerging in Cooking Oil Filtration Technology?

Cooking oil filtration has become an essential process in both commercial kitchens and home cooking to ensure food quality, safety, and cost-efficienc...

-

2025-12-23

How Do Cooking Oil Filter Papers Contribute to Healthier Cooking Practices?

Introduction to Cooking Oil Filter Papers Cooking oil filter papers are an essential tool for both home and commercial kitchens. Designed to remove im...

The Economic and Environmental Advantages of Reusable Non-Woven Cleaning Cloths

Reusable non-woven cleaning cloths are becoming a popular choice for both households and industries due to their economic and environmental benefits. Here’s a simplified breakdown of why these cloths are advantageous:

What Are Reusable Non-Woven Cleaning Cloths?

These cloths are made from fibers bonded together (not woven), making them soft, durable, and effective for various cleaning tasks. Unlike disposable options, they can be used multiple times.

Economic Benefits

Cost Savings: Although reusable cloths cost more upfront, they last longer, reducing the need for frequent replacements, saving money over time.

Durability: These cloths are built to last through many uses and washes, resisting wear and tear.

Versatility: They can be used for different cleaning tasks, reducing the need to buy multiple types of cleaning products.

Environmental Benefits

Less Waste: By reusing these cloths, you generate less waste compared to disposable options.

Resource Conservation: Using fewer disposable products helps conserve natural resources and energy.

Eco-Friendly Materials: Many of these cloths are made from recycled or biodegradable materials, making them more environmentally friendly.

Practical Tips for Use

Care: Wash according to instructions and avoid harsh chemicals like bleach to extend their life.

Maintenance: Regularly check for wear and replace them when necessary. Color-coding cloths can help avoid cross-contamination in different cleaning tasks.

Reusable non-woven cleaning cloths are cost-effective, durable, and environmentally friendly. They help reduce waste and costs while providing an efficient cleaning solution. By choosing these cloths, you can clean effectively while supporting a more sustainable future.

Bonding method for making nonwoven cleaning cloths

Nonwoven cleaning cloths are produced using various bonding methods, each affecting the cloth's properties such as texture, strength, and absorbency. Here's an overview of the primary bonding methods used in manufacturing nonwoven cleaning cloths:

Mechanical Bonding

How It Works: Fibers are physically tangled together using techniques like needle punching or hydroentanglement (spunlace), which uses high-pressure water jets.

Features: Soft texture, cost-effective.

Best For: General cleaning tasks where a gentle touch is needed, like household cleaning.

Thermal Bonding

How It Works: Fibers are heated and fused together using methods like calendaring (heated rollers) or ultrasonic bonding (sound waves).

Features: Strong, durable, consistent texture.

Best For: Heavy-duty cleaning and industrial use where strength is important.

Chemical Bonding

How It Works: Adhesives or chemicals are used to bond fibers, often through coating or spraying.

Features: Customizable properties, enhanced absorbency.

Best For: Specialized cleaning tasks, such as in healthcare or hospitality, where specific qualities are needed.

Needle Punching

How It Works: Barbed needles mechanically tangle fibers by passing through a fiber web.

Features: High density, durability, can be soft or rigid.

Best For: Industrial and heavy-duty cleaning where strength and resilience are crucial.

Spunbonding

How It Works: Melted polymer is extruded to form continuous filaments, which are then laid out and bonded by heat or pressure.

Features: Uniform strength, consistent texture, durable.

Best For: Both disposable and reusable cloths in environments requiring reliable performance.

Each bonding method gives the cloths different qualities, so the best choice depends on what you need, whether it's softness, durability, absorbency, or cost-effectiveness.

English

English Español

Español Household Cleaning

Household Cleaning

Personal Care

Personal Care

Car Care

Car Care

Pet Care

Pet Care

Cooking Oil Filter Papers

Cooking Oil Filter Papers